|

|

| SEISMIC RESTRAINT OVERVIEW | |

|

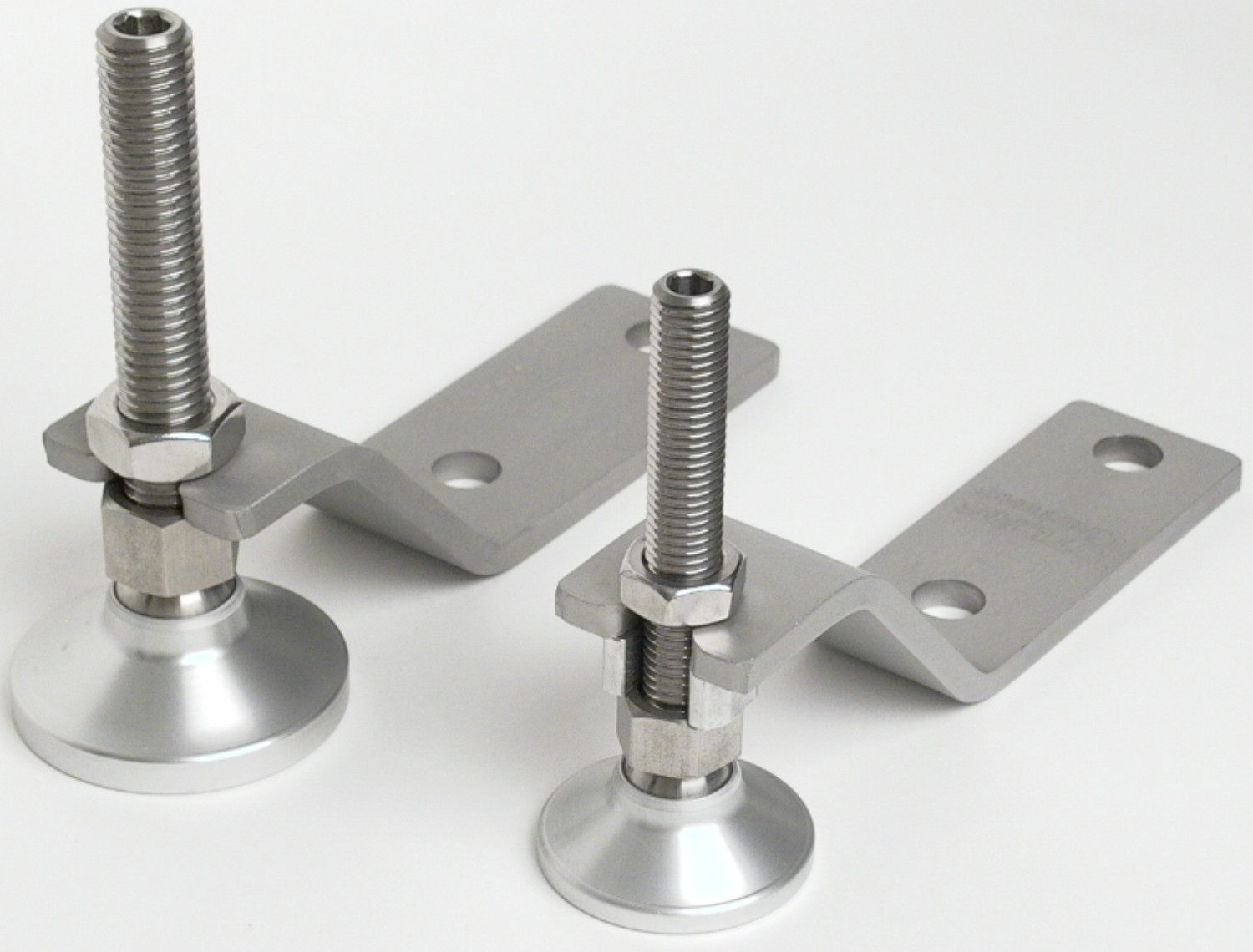

For equipment that is installed in earthquake prone areas, our seismic restraints may be used to secure equipment to the ground. These high strength stainless brackets attach to our leveling components to form a rigid connection that minimizes the build-up of seismic accelerations. |

|

| Product Features | |

|

|

| Vertical Testing | ||

|

Apparatus: A hydraulic press was fixtured to test a single restraint as shown. The head of a leveler stud was attached to the end of the piston and secured to the restraint with the locknut. Test: The piston was controlled by a PLC that was programmed move it rapidly up and down. The peak pull force was over 2,500 lbs and the test was run for 30 seconds. Results: The restraint withstood testing with no signs of yielding. For a movie, see the link below: |

|

|